Material Processing

API not only manufactures final products, but also has raw material processing technologies. Raw material processing broadens the possibilities of our products. One of API's strengths is that we could carry out a whole manufacturing from raw material processing to formulation and packaging under complete quality control.

- By utilizing processing technologies,

we turn raw materials to diverse forms and make products

go far beyond the framework. -

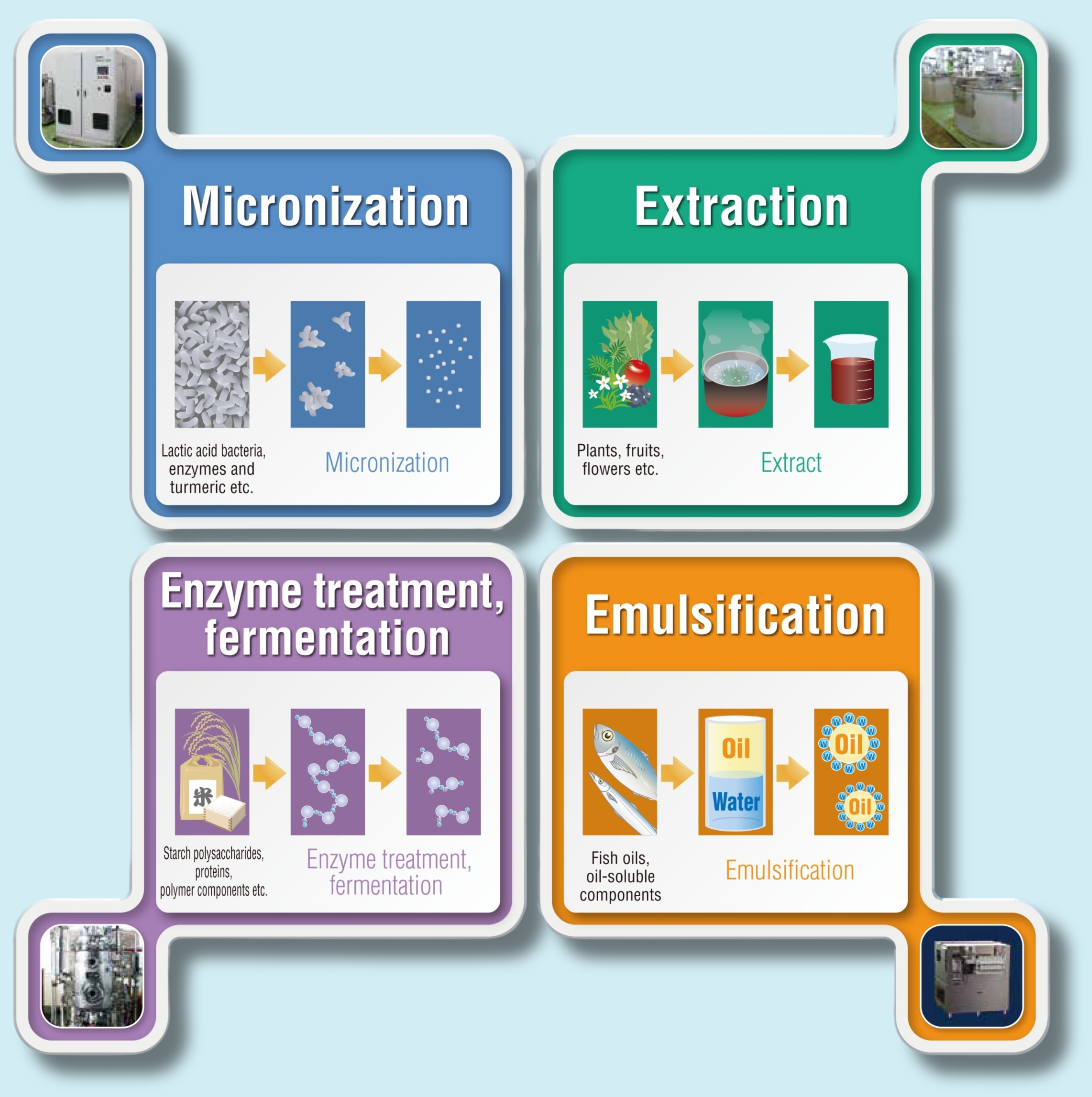

- Various kinds of Material Processing -

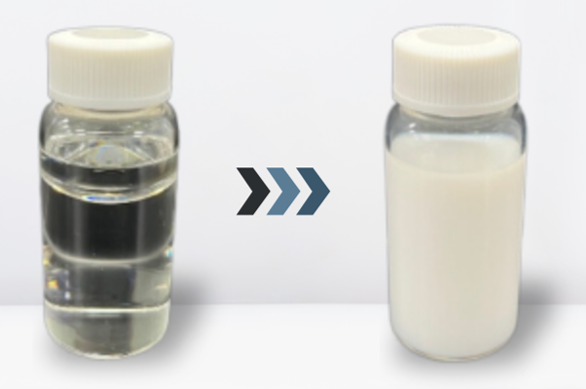

Emulsification makes it possible to add in oil ingredients that are originally not applicable to drinks. It could also be adapted for jellies.

With powderization, liquid raw materials become feasible to tablets and hard capsules.

(The most suitable method would be chosen from spray drying, lyophilization and centrifugal force dryer add mill )

(The most suitable method would be chosen from spray drying, lyophilization and centrifugal force dryer add mill )

With micronization, we makes poorly dispersible or poorly soluble raw materials applicable to drinks. It could also be adapted for jellies.

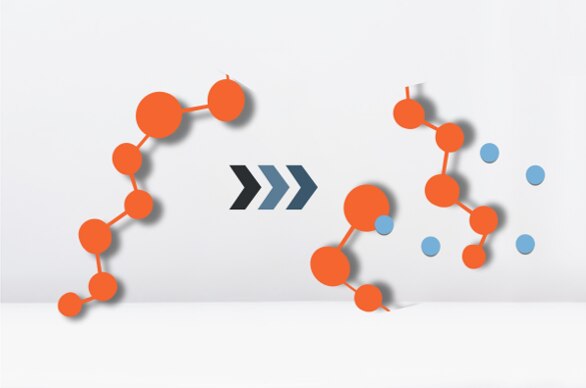

After adding water to the raw materials, they are subjected to high temperature, high pressure and shearing forces, and then immediately dried and powdered. The changes in physical properties improve their applicility to each dosage form.

With enzyme treatment, raw materials are improved with digestibility, functionality and flavor.

(Enzyme types: amylase, cellulase and protease)

(Enzyme types: amylase, cellulase and protease)

Raw materials are brought into contact with a solvent and dissolved in that solvent, which makes it possible to selectively isolate the soluble components. The main solvents used are water, ethanol, and hydrous ethanol.

- Virtual Factory Tour -

Extraction

Micronization

Powdering

- Other Line-Up -

Inquiry

Head Office

〒500-8558

1-1 Kanosakurada-cho, Gifu City, Gifu Prefecture

TEL: +81-58-271-3846

FAX: +81-58-275-0855

〒500-8558

1-1 Kanosakurada-cho, Gifu City, Gifu Prefecture

TEL: +81-58-271-3846

FAX: +81-58-275-0855

Tokyo Office

〒103-0023

Nihonbashi Honcho, Chuo Ward, Tokyo

3-7-2

MFPR Nihonbashi Honcho Building 5th floor

TEL: +81-3-3662-3878

FAX: +81-3-3663-2245

E-mail:

api-overseas-inquiry@api3838.co.jp

〒103-0023

Nihonbashi Honcho, Chuo Ward, Tokyo

3-7-2

MFPR Nihonbashi Honcho Building 5th floor

TEL: +81-3-3662-3878

FAX: +81-3-3663-2245

E-mail:

api-overseas-inquiry@api3838.co.jp

© copyright 2024 API Co., Ltd All Rights Reserved.