Functional Food Ingredients Library

Api Co., Ltd. has started a new business by making use of its experience and resources in ODM and OEM of supplements.

By using a clean manufacturing method that does not use any chemicals, we process materials such as grains and beans and add new functions to them.

Produces effective ingredients for PBF (plant-based food) and clean labels.

In addition to health functionality such as reduced salt, reduced sweeteners, and food allergies,

Contributes to functionality for food processability, upcycling and reduction of food loss.

Special material processing line

The high-order structure is loosened by high heat, pressure, and shearing force, and instantly powdered.

|

what you can do ・ Change of taste, improvement of flavor ・ Additive reduction and substitution effect ➡ Appropriate thickening, emulsification, and gelation ・ Easily degradable ➡ Improving the digestibility and absorption of ingredients, Reduction of enzymatic reaction time ・ Increased water retention and hydrophilicity ➡ Easy-to-process raw material with improved solubility and dispersibility Shortening the manufacturing process of food processing ・ Pregelatinized powder → Shortening of oxygen reaction time ・ Deodorizing and reducing the number of bacteria ・ Upcycle |

Usage example

Various grains and cereals Barley (barley, oats) Legumes (soybeans, peas, adzuki beans, chickpeas) Okara, rice bran, konnyaku, etc.

Labeling on the final product shall be based on the food ingredients Examples: Oat flour, rice flour, etc.

|

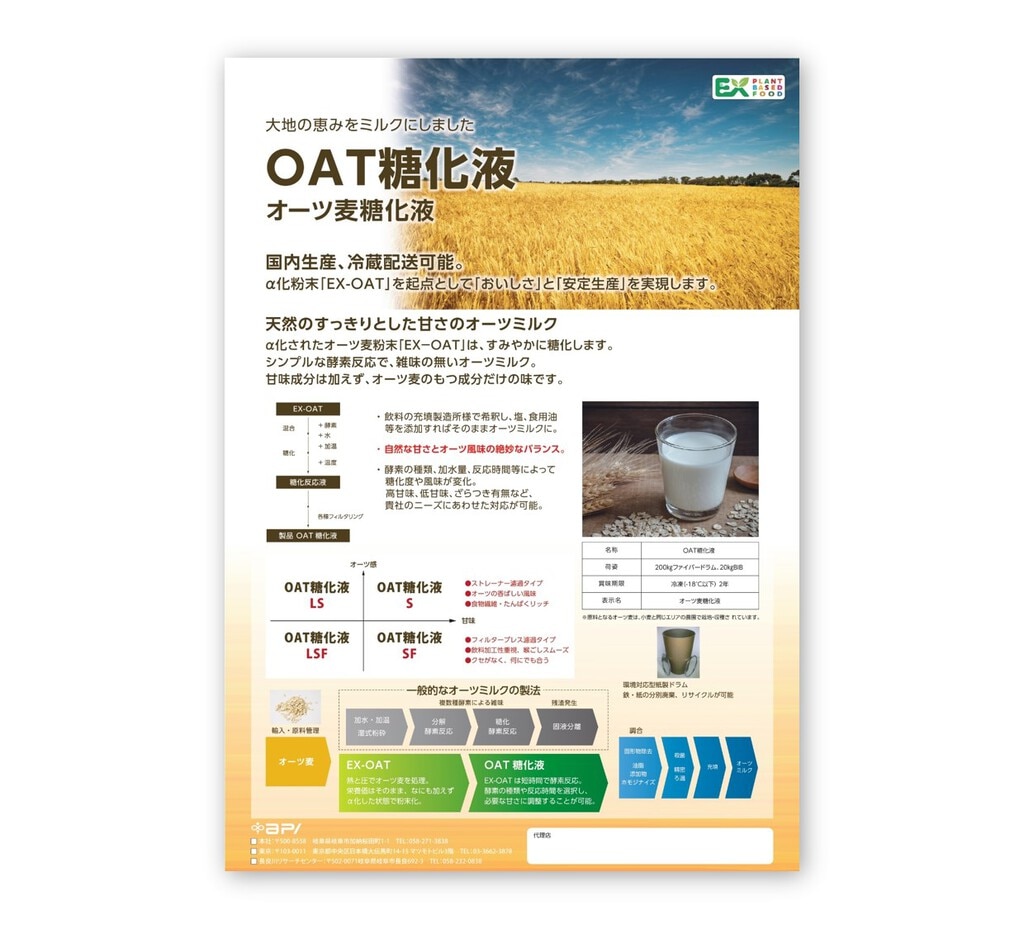

Saccharification liquid production line

Liquid raw material production line for sterilization, etc.

Combined with special material processing, it is possible to manufacture various vegetable milks (saccharified liquids)

|

what you can do ・Saccharification of raw materials, decomposition, filtration, purification, sterilization, etc. ・Sweetness adjustment ➡ You can adjust the sweetness to your liking with the type of enzyme ・Filtration adjustment ➡ The mesh size can be changed according to the application.

|

Usage example

Cereals (rice, cereals) Barley (barley, glutinous barley, oats) Legumes (soybeans, peas, adzuki beans, chickpeas) Potatoes (potatoes, sweet potatoes)

Such

|

Easy bacteria count management in combination with special material processing!

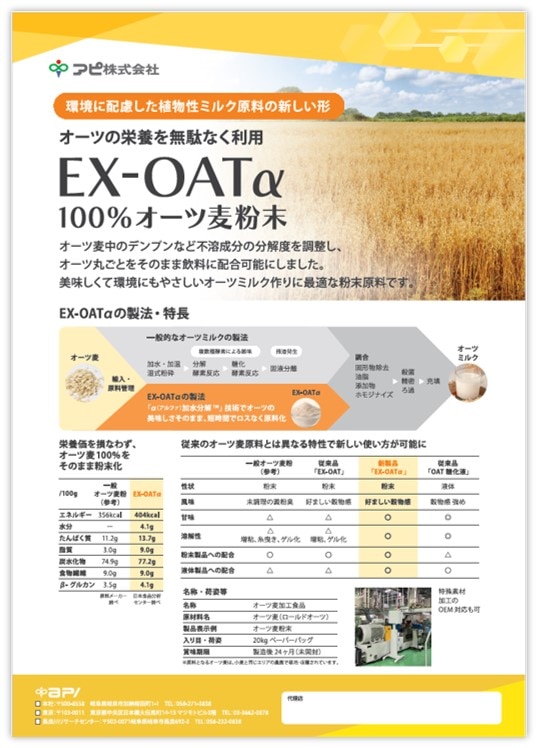

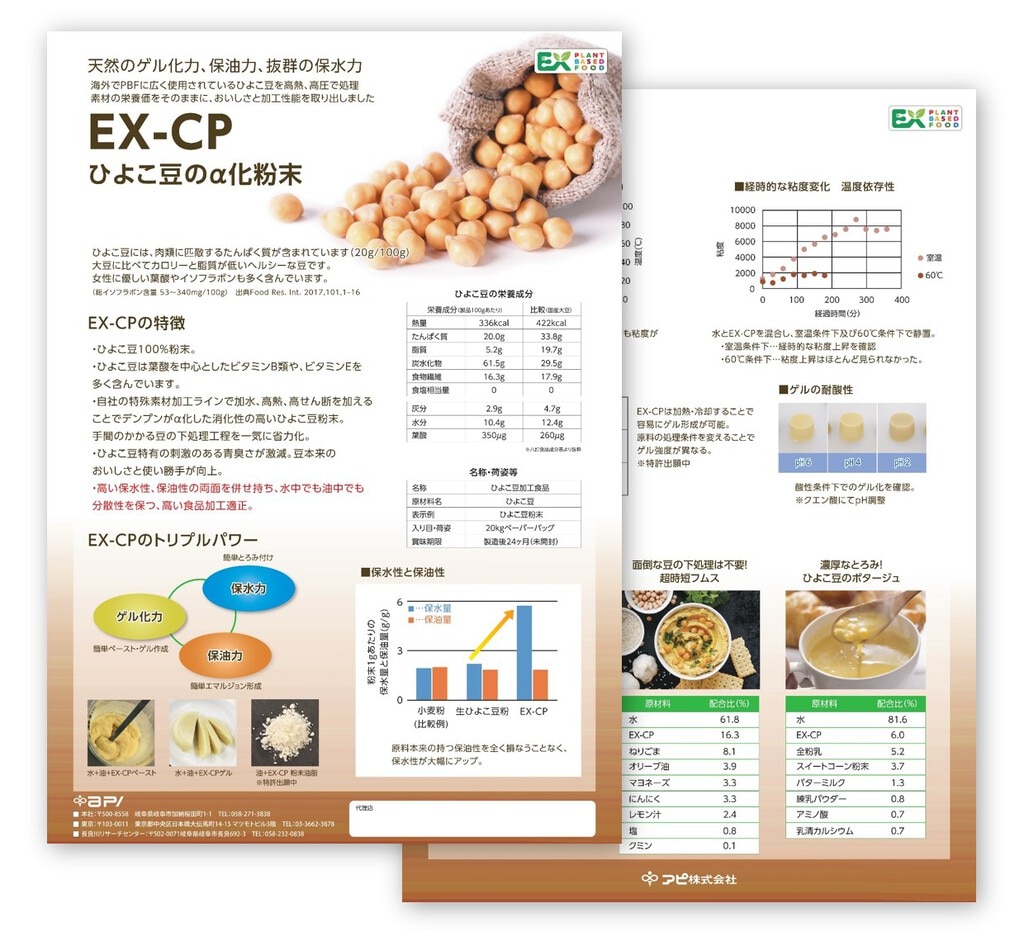

Document list

Please contact us from the inquiry form or contact us by phone.

API Co., Ltd. Functional Food Ingredients Division

(TEL: 058-232-0838)

It has been featured in many media!

Click here for media coverage page